Features and Advantages

Features and Advantages

Quality control Precise energy control to effectively prevent burns

around the pad.

Precise pressure control to effectively prevent the pad

from collapsing.

Real-time welding pressure inspection to give an alarm

when the preset range is exceeded.

Intelligence Visual recognition and automatic regrinding of welding head to ensure the accuracy of welding position and improve the welding quality.

Application Fields

Application Fields

Core Modules

Core Modules

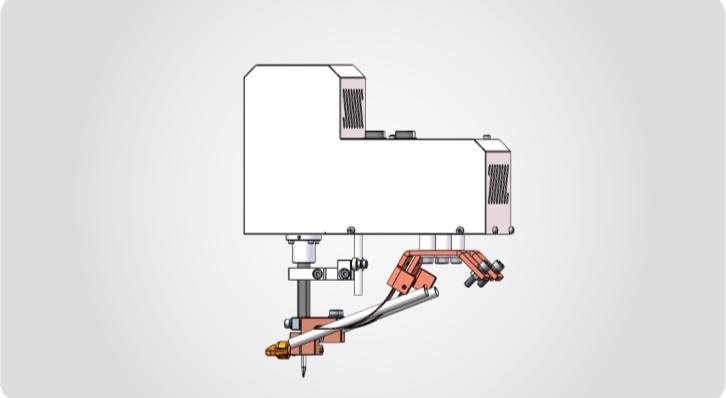

Vision Module

The CCD can automatically recognize the position of enameled wire and guide the work platform to complete precise welding

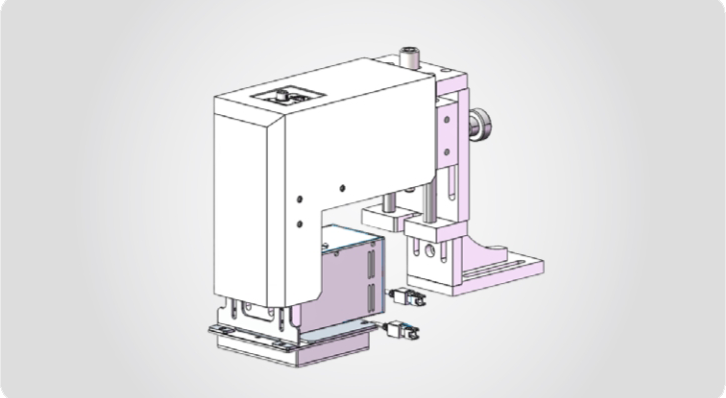

Precision Pressure Head

Closed-loop pressure control with the error of ±5g, and real-time pressure inspection to improve the welding quality

Precision Transistor Power Supply

Closed-loop energy control to quickly achieve stable output and effectively prevent pad burns caused by energy diffusion

Ceramic Regrinding Module

Achievement of automatic regrinding after the set number of workpieces for spot welding is reached