Features and Advantages

Features and Advantages

Achievement of high-speed and high-precision

dispensing Grating ruler positioning and linear motor drive to ensure

the dispensing accuracy and stability.

Good shock absorption with mineral frame structure

pioneering in the industry to effectively reduce the

impact caused by the high-speed operation of the

equipment.

Whole-process inspection Product status inspection before operation, and glue status inspection after operation.

Efficient model changeover Suitable for a variety of dispensing process requirements to achieve quick model changeover.

Meeting information management requirements Docking with MES system to upload the production status information in real time and give an alarm and trace in case of any abnormity.

Suitable for a variety of processes Modular design to provide process modules such as inline, double-track, double-valve, 360° T/R, bottom heating, weighing, and loading & unloading.

Core Modules

Core Modules

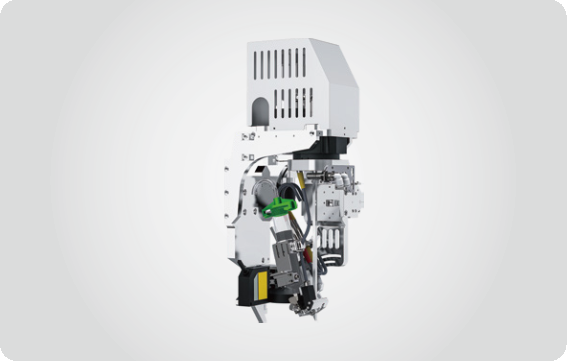

T/R Module

Suitable for side dispensing process

360° Rotation Module

Suitable for 360° obstacle-avoidance dispensing process

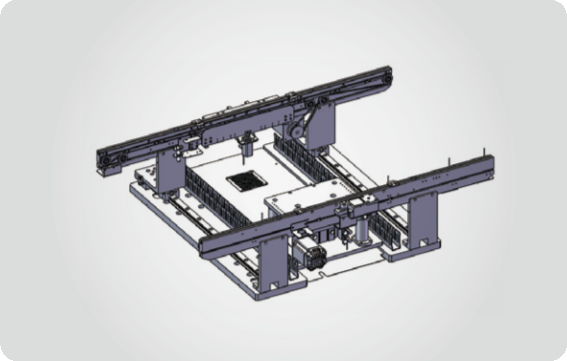

Track Conveying Module

Product positioning and conveying functions

Optional single-track / double-track modes

Application Fields

Application Fields

Optional Configurations

Optional Configurations