Features and Advantages

Features and Advantages

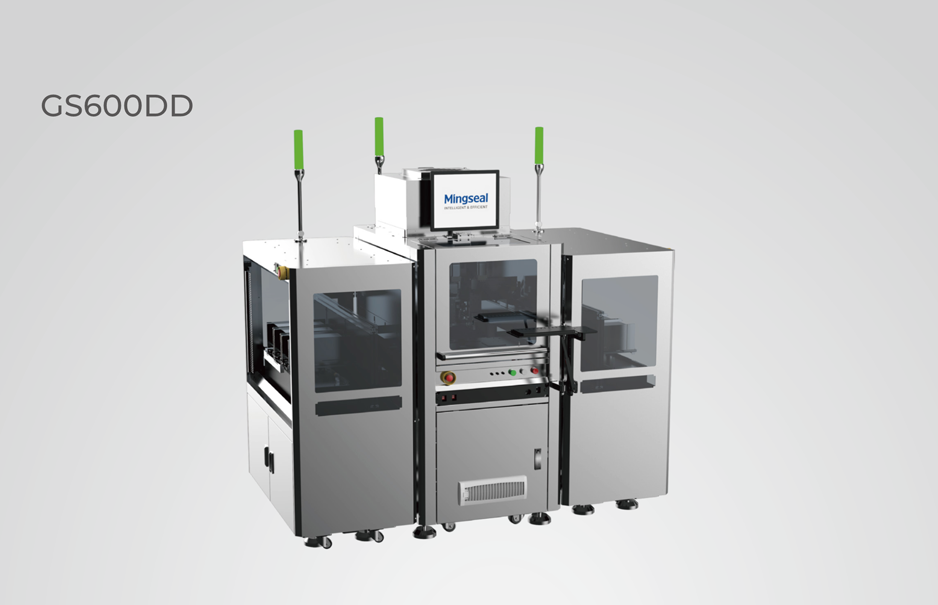

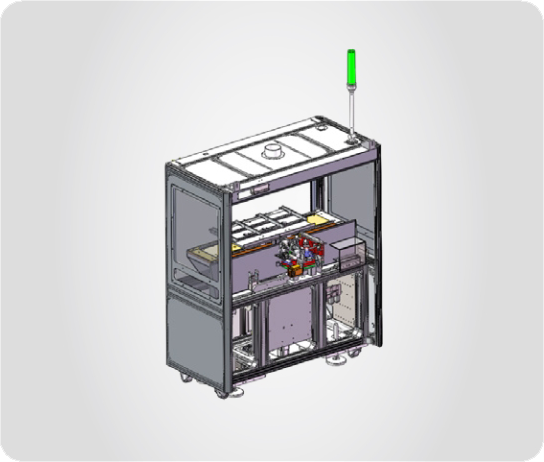

Good shock absorption with mineral frame structure pioneering in the industry to effectively reduce the impact caused by the high-speed operation of the equipment.

Glue weight detection method combining capacitive detection + photoelectric detection to avoid poor batch operation caused by lack of glue.

Automatic dispensing position compensation function to ensure the dispensing accuracy.

Glue width detection function to avoid process risks caused by poor dispensing.

Dustproof class 100 (Class 100 workshop; Class 10 locally), meeting the packaging environment requirements.

ESD protection meeting international IEC and ANSI standards.

Application Fields

Application Fields

Core Modules

Core Modules

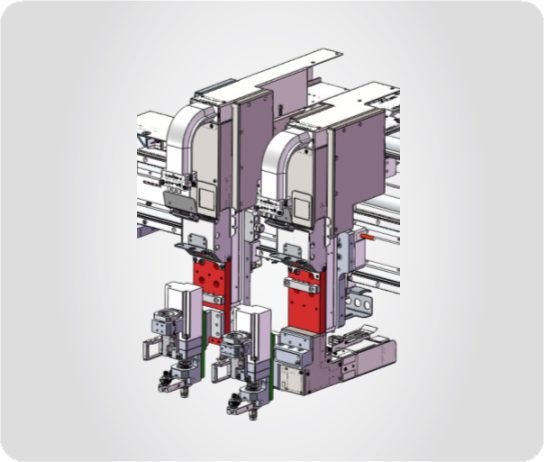

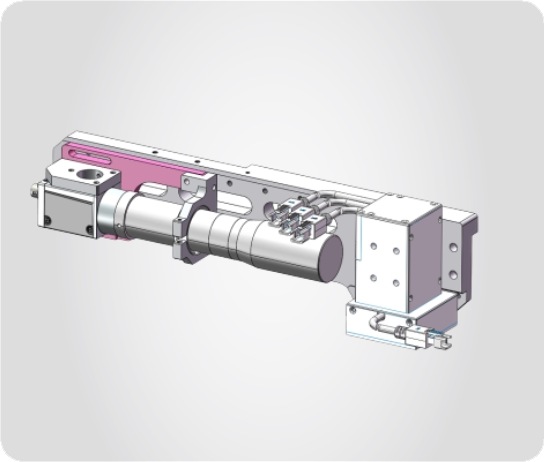

Double-Valve Synchronization (with Interpolation) Module

correction separately for double valves

Simultaneous operation of double valves to improve the production efficiency

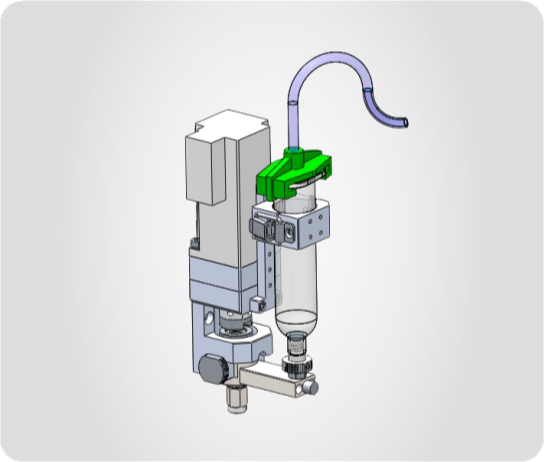

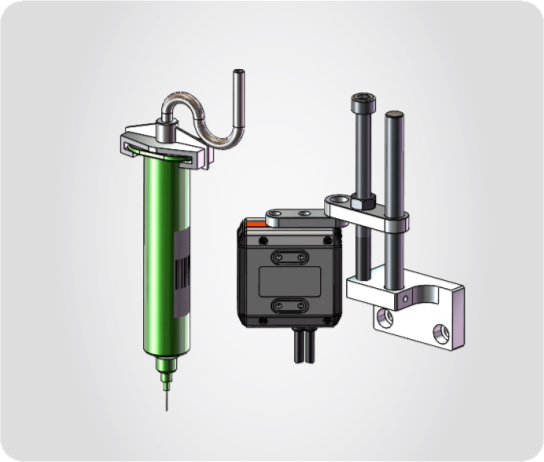

Piezoelectric Jetting System

Suitable for filling or coating of low-viscosity adhesives such as Fill

Screw Dispensing System

Suitable for coating of high-viscosity adhesives such as Dam and Tim

Glue Tank Scanning Module

Automatic reading of tank QR code information to prevent poor operation caused by glue mixing / expired glue

Visual System

Positioning and detection functions

Inspection before operation to avoid defective incoming materials

Inspection after operation to prevent batch defects

Platform-Type Loading & Unloading System

Automatic sorting of feeding sequence

Completion of operation within Plasma time limit

Friendly human-machine interface design