Features and Advantages

Features and Advantages

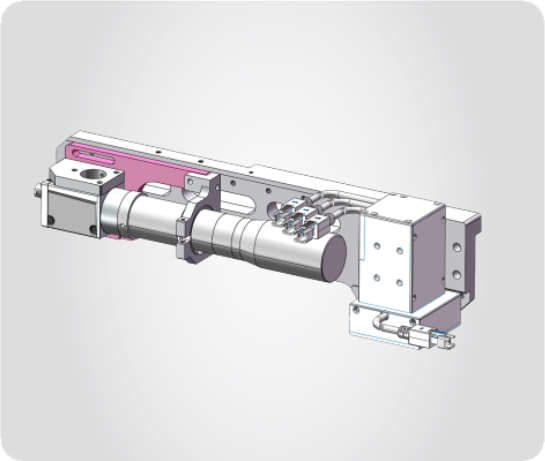

Achievement of high-speed and high-precision dispensing Grating ruler positioning and linear motor drive to

ensure the dispensing accuracy and stability.

Good shock absorption with mineral frame structure

pioneering in the industry to effectively reduce the

impact caused by the high-speed operation of the

equipment.

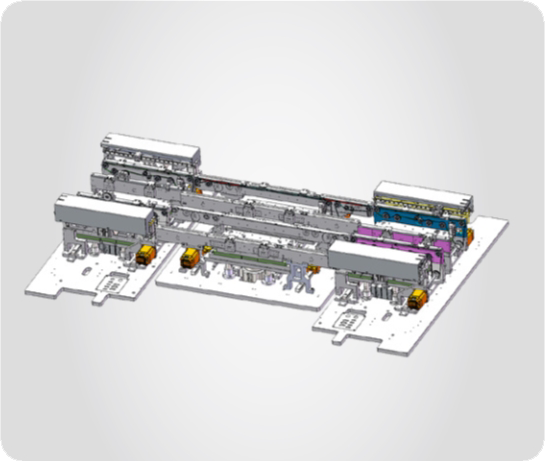

High compatibility Adjustable track width, compatible with substrates / carriers of different sizes & specifications, and standard track width adjustment range of 60-162mm.

Efficiency improvement Simultaneous operation of double tracks to save the

carrier plate turnover time.

Three-segment heating to reduce the operation waiting

time.

Meeting information management requirements Docking with MES system to upload the production

status information in real time and give an alarm and

trace in case of any abnormity.

Compatible with international semiconductor communication protocols.

Application Fields

Application Fields

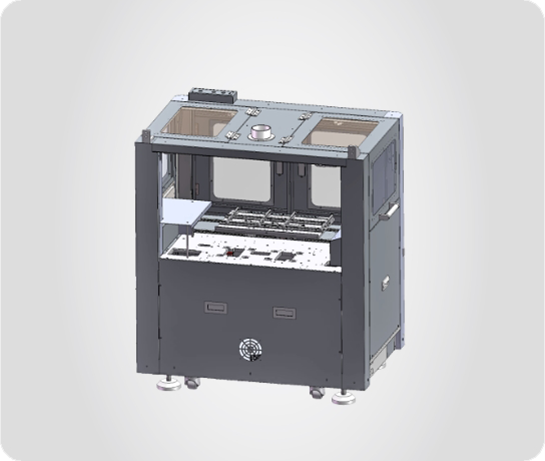

Core Modules

Core Modules

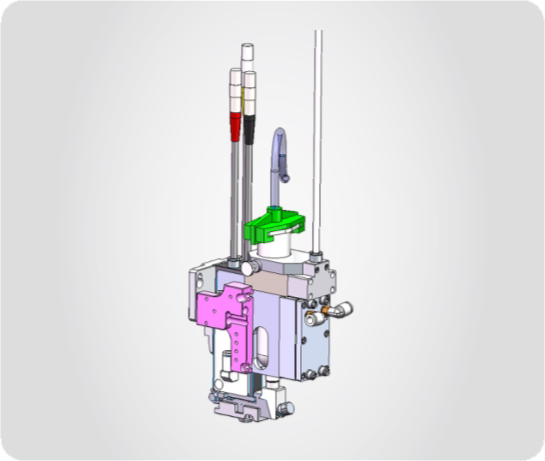

CUF Special Piezoelectric Jetting System

Adhesive insulation + piezoelectric ceramic temperature closed-loop control to avoid system instability caused by temperature influence

Triple Low-Level Alarm Module

Capacitive detection + photoelectric detection + system weighing to avoid poor batch operation caused by lack of glue

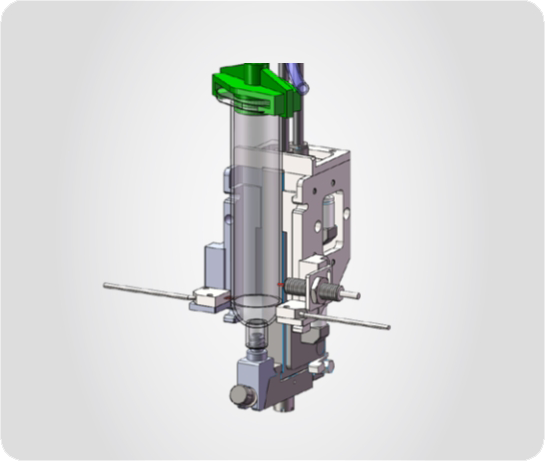

Process Module

Automatic glue residue cleaning, automatic weighing and glue amount calibration functions

Visual System

Positioning and detection functions

Inspection before operation to avoid defective incoming materials

Inspection after operation to prevent batch defects

Vacuum Adsorption & Heating Fixture

Temperature difference of whole fixture surface ≤ ±1.5°C

compensation to avoid poor operation caused by product temperature variation during operation

Platform-Type Loading & Unloading System

Automatic sorting of feeding sequence

Completion of operation within Plasma time limit

Friendly human-machine interface design