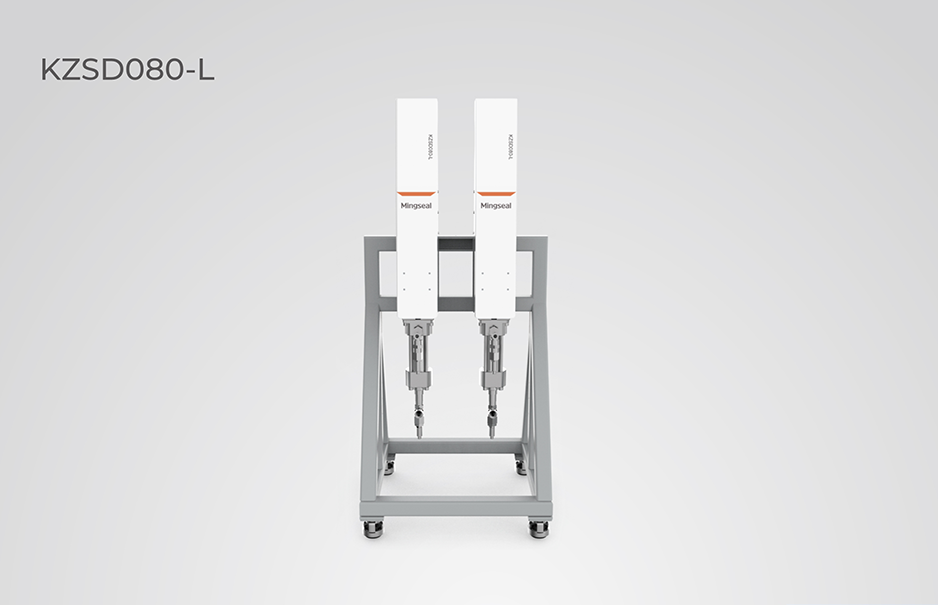

Features and Advantages

Features and AdvantagesThe ceramic plunger is adopted to achieve longer life when applying high-packing glue.

The total dispensing flow rate can be 35cc/s at maximum.

There is no packing time, so that the product coating time is shortened;

Real-time pressure monitoring at the feeding end and metering end.

Applicable Fluids

Applicable Fluids Application Fields

Application Fields Application Fields

Application Fields

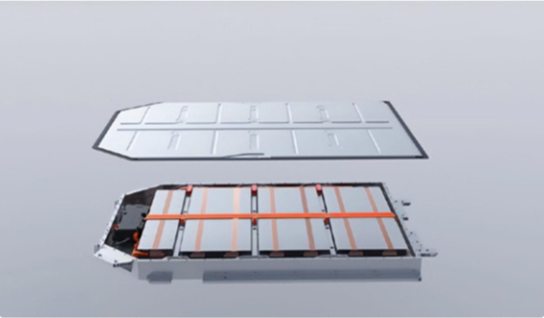

Battery

Automobile

General Industry

Technical Specifications

Technical Specifications| Indexes | Parameters and Performance |

| Pump A + pump B cylinder body volume | 160ml |

| Max. flow rate | 35ml/s |

| Max. operating pressure | 20MPa |

| Glue inlet port | G3/4 male thread |

| Dispensing port | G1/2 male thread |

| Fluid parts | Tungsten steel, stainless steel, PTFE, UHMWPE and silicon nitride |

| Applicable viscosity | 20-1000000mPas |

| Dimensions (W*D*H) | 1355*600*550mm |

| Weight | 100kg (including bracket) |

| Operating noise | < 75dB |