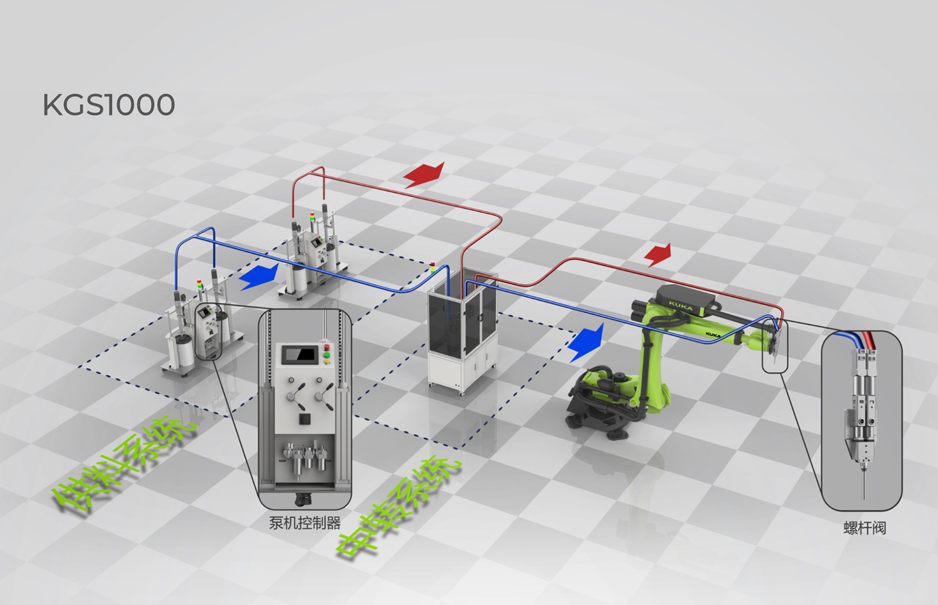

System Composition

System Composition Features and Advantages

Features and AdvantagesCompared with the traditional pneumatic platen pump, the servo screw platen pump can save energy by more than 300%.

The servo screw platen pump runs more quietly, and its noise during normal operation does not exceed 70 decibels.

The composition of the whole system is reduced to make operation and maintenance easier.

Compared with the plunger pump, the screw pump has a simple structure, achieving short maintenance time and greatly reducing the cost of consumables.

The liquid receiving part is made of special wear-resistant material, increasing the service life and extending the maintenance cycle.

Compared with the traditional plunger pump, the operating pressure of the screw pump is lower, which is more conducive to ensuring the originality of the glue.

Modular management of glue supply system and transit system.

Adaptive to the personalized layout of the production line, reducing the impact of the glue pipe pressure loss on the accuracy.

Various closed monitoring loops which are convenient for glue supply, secondary glue supply and terminal metering.