System Composition

System Composition Features and Advantages

Features and AdvantagesDamage-free automatic handling of wafers in magazines and between magazines.

Optional Bernoulli fingers for thinning wafers.

Customized production to meet customer needs.

Meeting customers’ needs for multiple/different types of magazines and transfer of wafers with different sizes.

Provided with automatic opening mechanism for magazines.

Provided with efficient filtering device (HEPA specification).

ESD protection meeting international IEC and ANSI standards.

Supporting semiconductor-related automation protocols.

Optional OCR module for Wafer ID, which can deal with barcodes, QR codes, numbers and letters.

Application Cases

Application CasesFully-Automatic Wafer Dispensing System

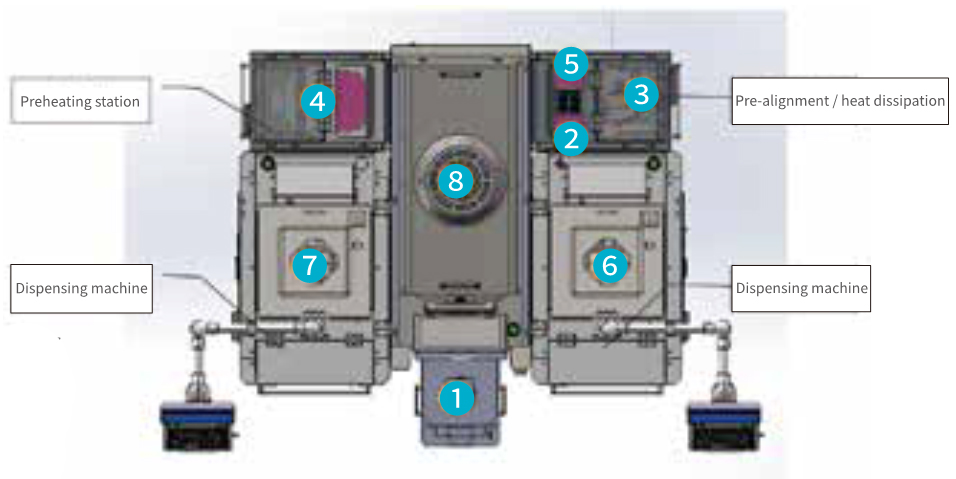

Main System Composition

❶ Loadport&Foup ❷ Aligner ❸ Code scanning station ❹ Preheating station ❺ Heat dissipation station ❻ Dispensing machine ❼ Dispensing machine ❽ Manipulator handling module

Case Description:

The EFEM mainly performs wafer pre-processing and transfer for wafer-level dispensing machines, and is compatible with 8-inch/12-inch products and mainstream dispensing equipment in the market. It can realize functions such as automatic wafer handling, alignment, preheating, operation heating and heat dissipation. It is compatible with international semiconductor communication protocols, and is provided with an AMHS automatic loading & unloading robot interface to match the information management requirements and unmanned management trends.

Serial Flip-Chip Reflow Operation

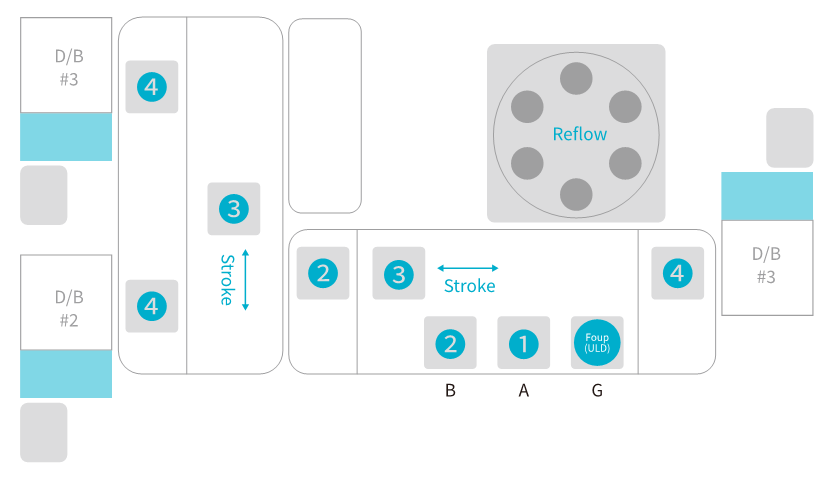

Main System Composition

❶ Loadport&Foup ❷ Aligner+OCR ❸ Manipulator handling module ❹ Conveyor track

Case Description:

The system is suitable for serial operation of flip-chip reflow equipment, and integrates automatic wafer loading & unloading and flip-chip reflow operations. It can realize functions such as automatic wafer handling, alignment, wafer ID reading, and product transfer between different devices. It is compatible with international semiconductor communication protocols, and is provided with an AMHS automatic loading & unloading robot interface to match the information management requirements and unmanned management trends.