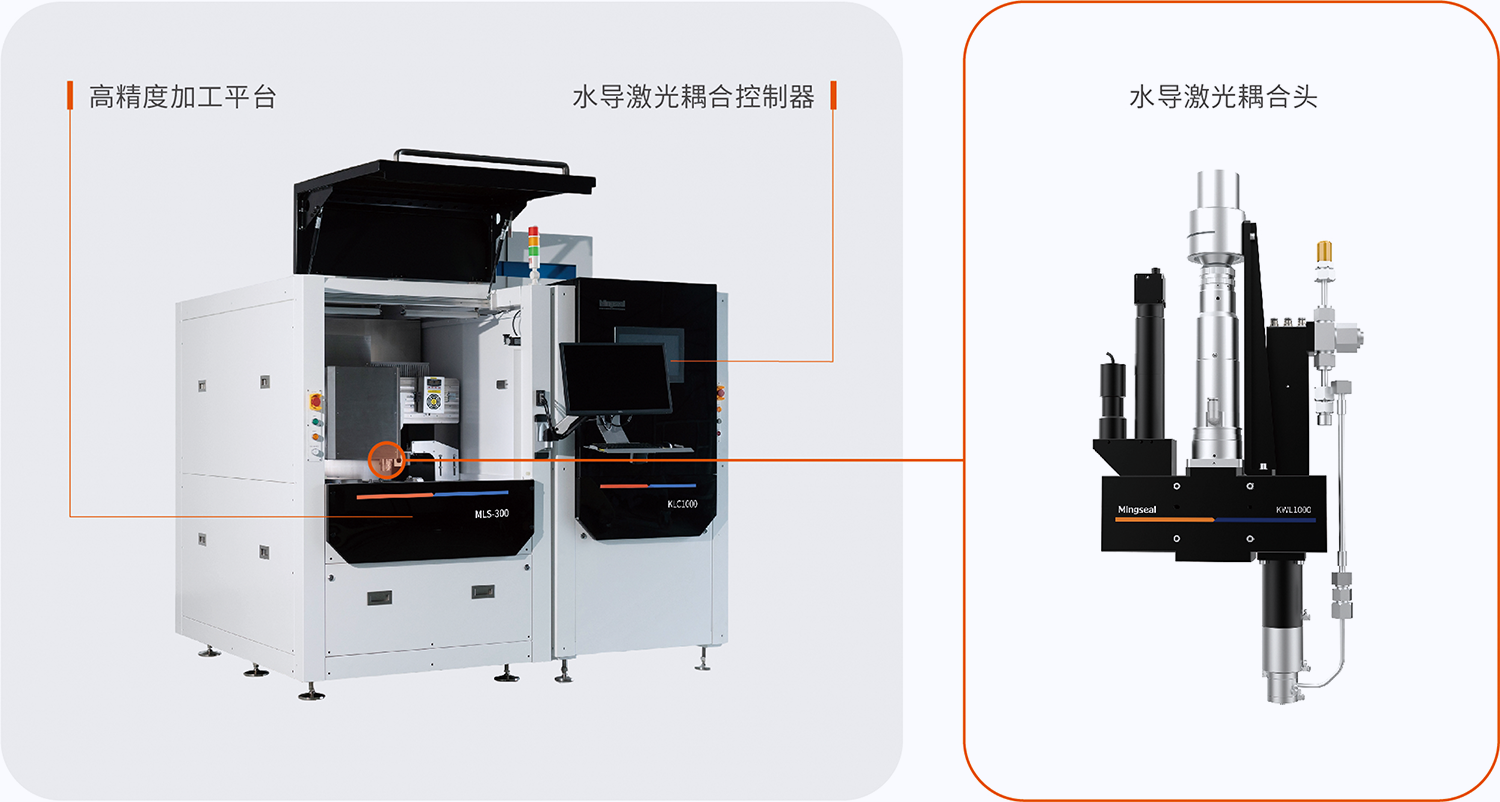

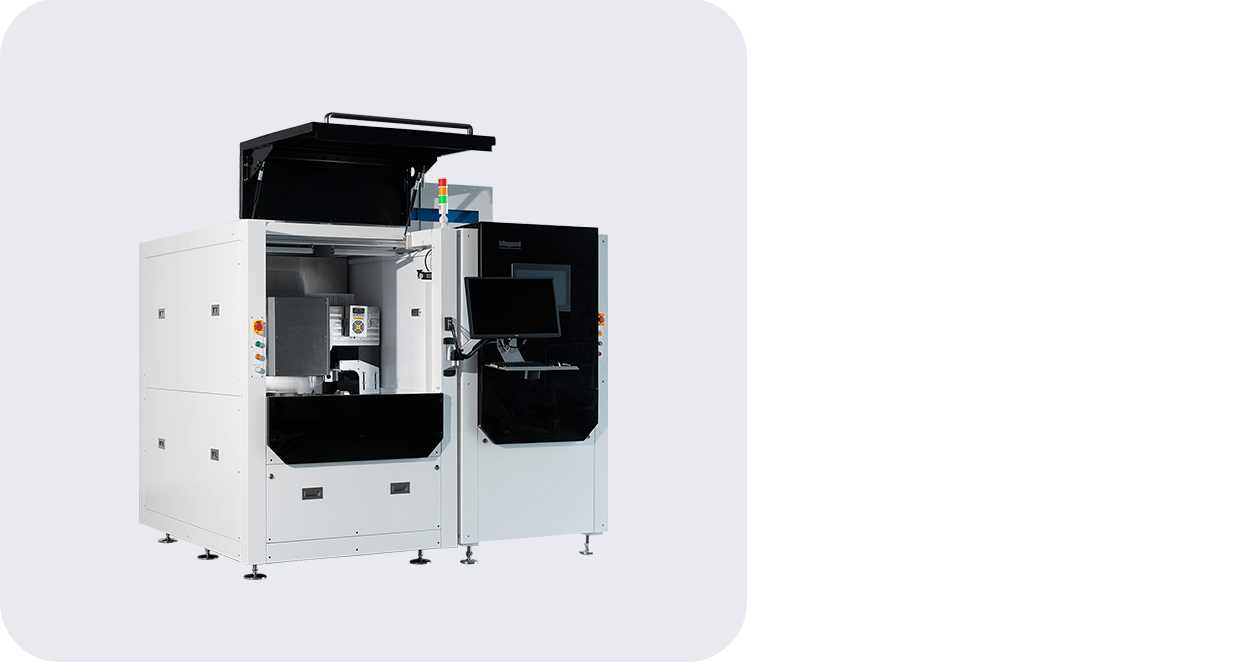

The MLS300 ultra-precision water jet guided laser machining system, self-developed and manufactured by Mingseal, enables micro-precision processing with accuracy within ±10μm on materials of various thicknesses and hardnesses, including ceramic substrates, liquid metals, wafers, diamond heat sinks, silicon carbide, and more.

It is capable of ultra-precision processing on fragile materials such as ceramic substrates, wafers, and thin alloy sheets, as well as handling hard materials like silicon carbide(SiC), boron nitride(BN), carbon fiber (CF), and diamond, with a cutting depth-to-width ratio exceeding 30:1.

High-precision jetting angle auto-calibration system combined with ±0.2MPa water pressure control for superior cutting flatness.

Carbon-based Diamond

Carbon-based Diamond

Copper-based Diamond

Copper-based Diamond

Boron Nitride

Boron Nitride

Alumina Ceramic

Alumina Ceramic

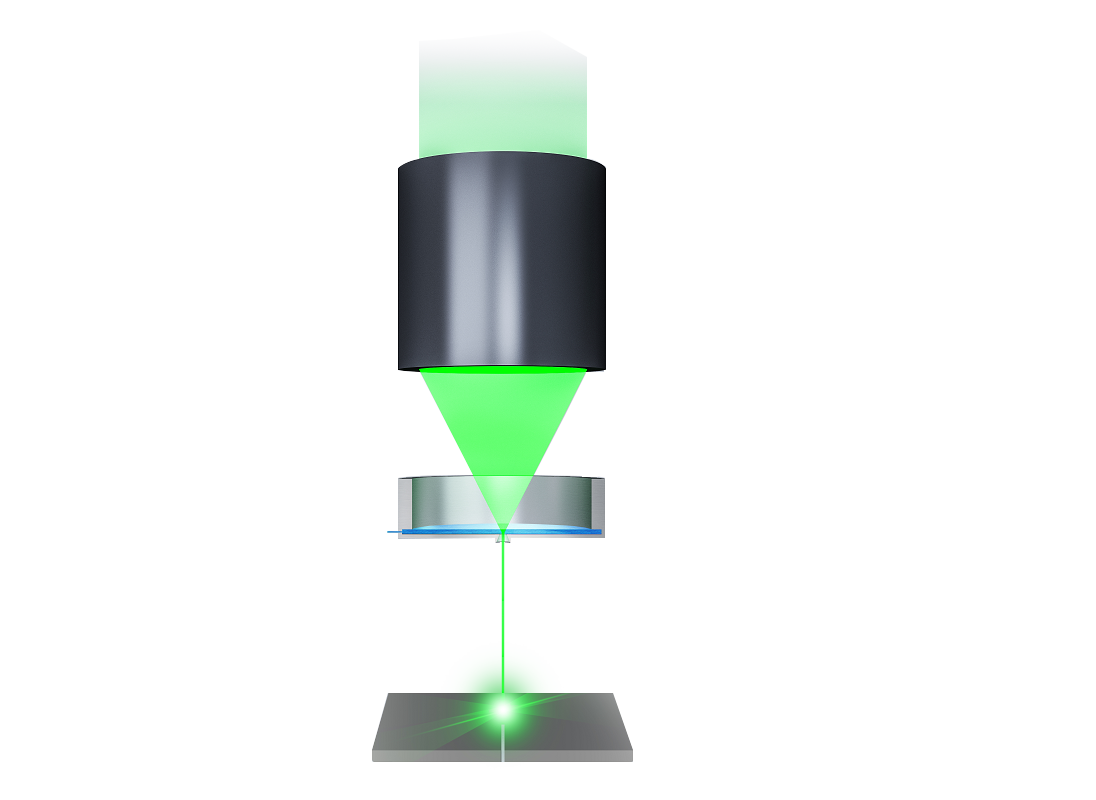

When a laser beam is focused into a micro-scale water jet and travels toward the water-air interface, total internal reflection occurs if the incident angle is smaller than the critical angle, allowing the laser to be efficiently guided forward within the water column.

Based on this principle, by precisely controlling the focal spot size and incident angle, the laser energy can propagate stably and accurately along the water jet, enabling high-quality, high-efficiency processing on the material surface.

| Class |

Water Jet |

Consistent Laser Illustration |

Ultrafast Laser Illustration |

| Heat Affected Zone |

≤5μm

|

>500μm

|

≤5μm

|

| Cutting Depth-to-width Ratio |

≥30:1

|

10:1

|

20:1

|

| Min. Kerf |

25μm

|

>100μm

|

50-100μm

|

| Cutting Taper |

Basically |

Obviously

|

Thickness≤0.3mm |

| Cutting Burr |

Burr-free, |

Obvious burrs, |

Thickness≤0.3mm |

| Cleanliness |

Auto debris removal by water flow, |

Post-process surface cleaning required |

Post-process surface cleaning required |

| Environmental Friendliness |

No dust or |

Generate dust and |

Generate dust and |