Features and Advantages

Features and Advantages

Quick response Integrated direct-connection design of electromagnetic valve and valve body eliminates air-feeding delay between the controller and the valve, enabling high-speed spray response.

Precise adjustment Use high-precision stroke adjuster for accurate glue

volume control.

Equipped with a high-precision air pressure regulator

and stabilizing pressure module to ensure stable air

output.

Low-pressure atomization Low-pressure atomization prevents over-spraying, mist and splashing.

Micro-spraying Enable precise spraying of medium and low viscosity fluids at mg-level (flux spray minimum glue weight: 1 mg; minimum line width: 2 mm).

Uniform coating Ensure consistent spraying with excellent uniformity and edge definition (Flux spray pattern range<1mm).

Easy process debug By controlling the timing between atomizing and valve-opening air pressure, it effectively prevents glue accumulation at the start and end of the line, ensuring consistent glue lines.

Friendly interaction Equipped with LCD screen and flexible buttons to support real-time visualization of parameters (such as supply air pressure and atomizing pressure), easily switching the mode with one button, and feeding back real-time system status.

Application Fields

Application Fields

Technical Specification

Technical Specification

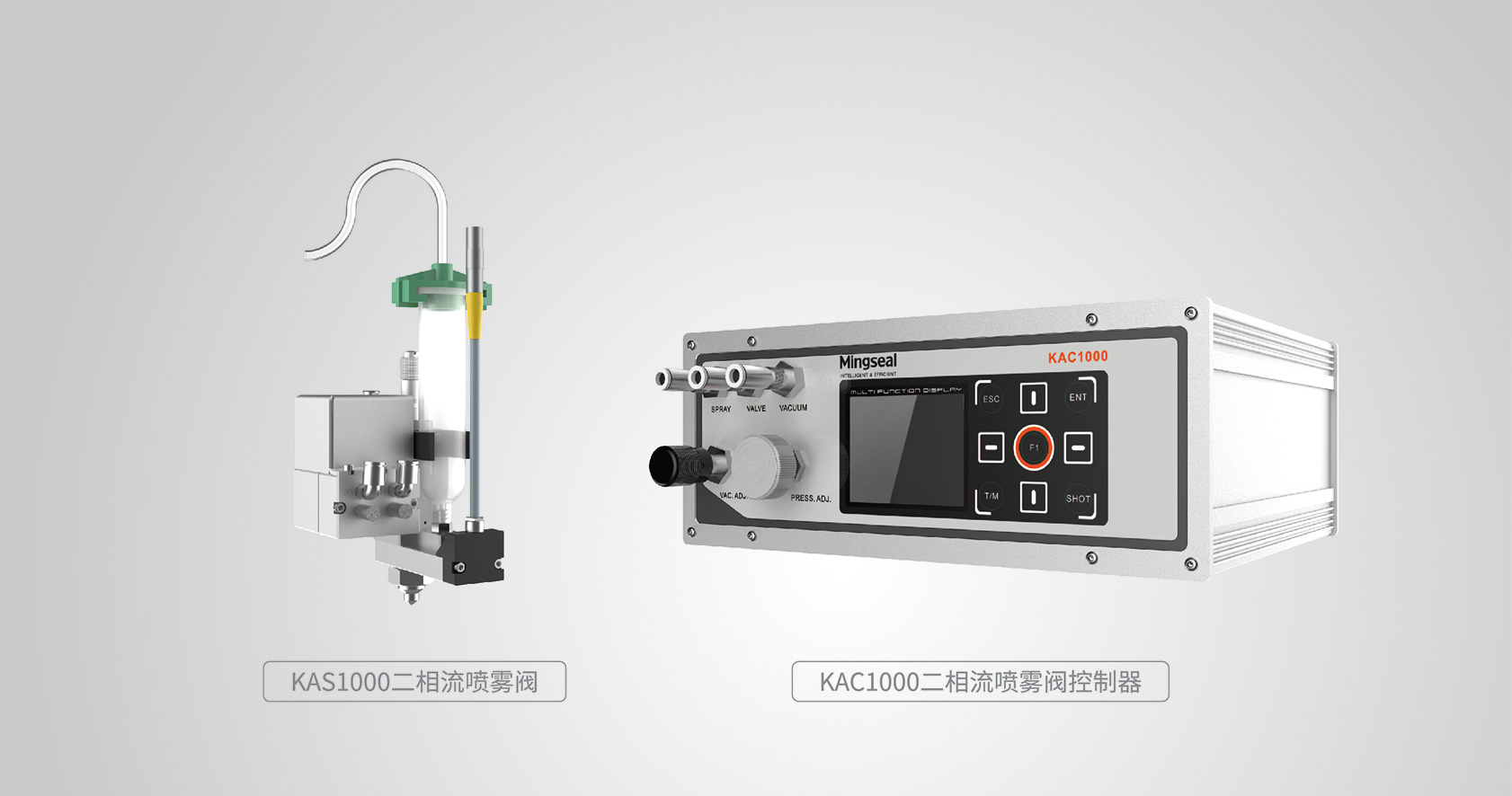

| Model | KAS1000 |

| Input Air Pressure | 0.4~0.5MPa |

| Valve-opening Air Pressure | 0.4~0.5MPa |

| Min. Sawtooth Range | 1mm(Flux Spray) |

| Min. Spraying Glue Weight | 1mg(Flux Spray) |

| Applicable Viscosity | 1~1500mPa·s |

| Max. Atomizing Pressure | 0.2MPa |

| Max. Fluid Pressure | 0.6MPa |

| Min. Spraying Width | 2mm(Flux Spray) |

| Min. Glue Thickness | 15μm |

| Valve Material | Piston rod, Fluid groove (stainless steel) |

| Needle&Nozzle Component Material | Tungsten steel |

| Sealed Component | UPE, Perfluoroether rubber, PTFE |

| Dimensions(W×D×H) |

Valve: 10714591mm(Include Heating Module) Controller: 260250100mm |

| Weight |

Valve: 1.1kg(Include Heating Module) Controller: 3.1kg |

Applicable Fluids

Applicable Fluids