Features and Advantages

Features and Advantages

Stable equipment operation Good shock absorption with one-piece cast mineral frame structure pioneering in the industry to effectively reduce the impact and vibration caused by the high-speed operation of the equipment and ensure the long-term operation stability of the equipment.

Supporting inline automatic operation of multiple sets Optional inline mode to minimize manual intervention.

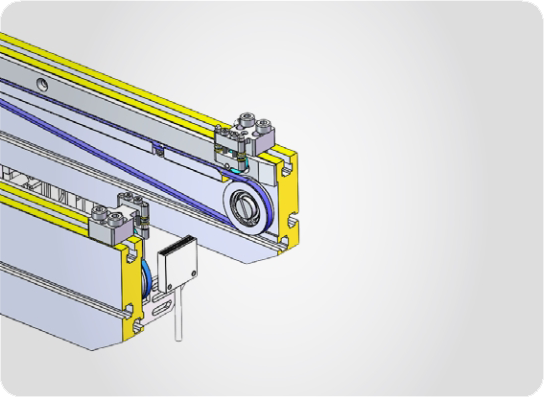

Separation of operation tracks / conveyor tracks to prevent whole line downtime The operation tracks / conveyor tracks are operated separately, so that shutdown of a single machine does not affect the operation of the whole line.

Whole-process inspection Work positions are inspected before and after operation, and the final station is professionally inspected to achieve multiple fool proof.

Meeting stringent engineering requirements Dustproof class 100, meeting the requirements of

advanced packaging industry.

ESD protection meeting international IEC and ANSI

standards.

Meeting information management requirements Docking with MES system to upload the production

status information in real time and give an alarm and

trace in case of any abnormity.

Compatible with international semiconductor communication protocols.

Application Fields

Application Fields

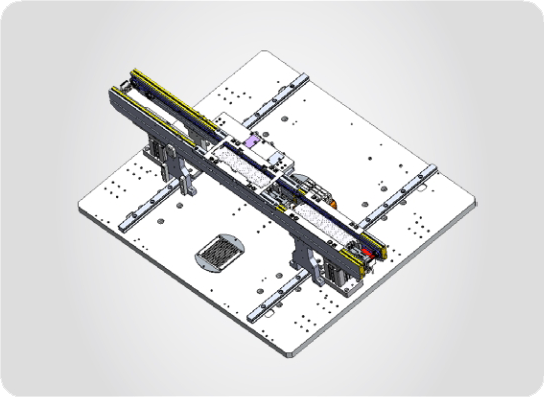

Core Modules

Core Modules

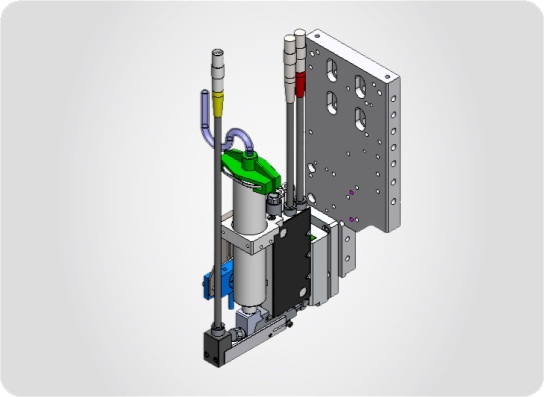

Single-Valve Dispensing Module

Non-contact dispensing to match precise dispensing of low-viscosity adhesives such as Coating and Fill

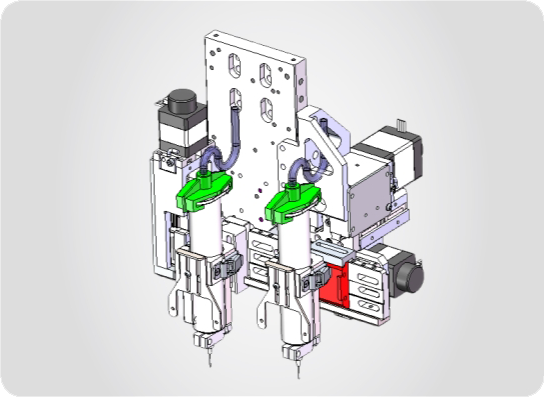

Double-Valve Solder Paste Printing / Dispensing Module

Synchronized control of double valves to achieve more efficient operation

Double valves can be fine-tuned according to the position of the material plate

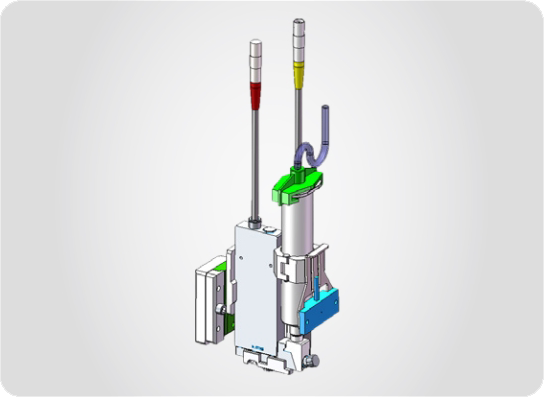

Low-Level Alarm Module

Avoiding poor operation caused by lack of glue

Visual System

Positioning and detection functions

Inspection before operation to avoid defective incoming materials

Inspection after operation to prevent batch defects

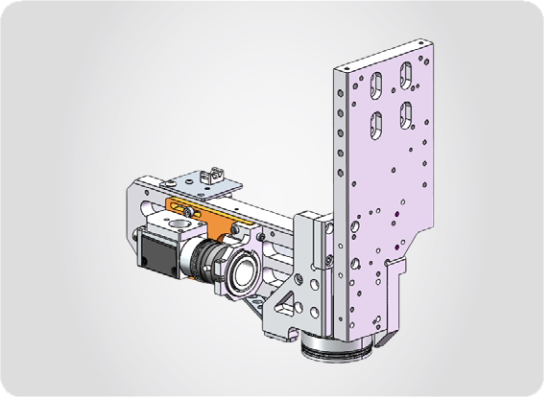

Lateral-Pushing Module

Lateral angle correction of materials to ensure accurate positioning of materials

Pinch Roller Mechanism

Avoiding poor operation caused by warping of thin substrates during conveying