Features and Advantages

Features and Advantages

Achievement of high-quality and high-precision dispensing Grating ruler positioning and linear motor drive to ensure the dispensing accuracy and stability.

Convenient equipment structure Front and rear double-flip doors (gull-wing doors) to

facilitate direct observation, debugging and picking &

placement of carrier plates.

Double display components and alarm lamps making it

easier to operate and observe.

Efficiency improvement Simultaneous operation of double tracks to save the

carrier plate turnover time.

Supporting double heads and double valves to realize

synchronous / asynchronous dispensing, thus improving

the operation efficiency.

Supporting the supply of glue from large-volume glue

tanks to reduce the replacement frequency.

High compatibility Adjustable track width, compatible with products of

different sizes & specifications, and possible connection

of multiple sets.

Supporting Max. 2600mm*800mm carrier plate to realize

completion in one operation.

Core Modules

Core Modules

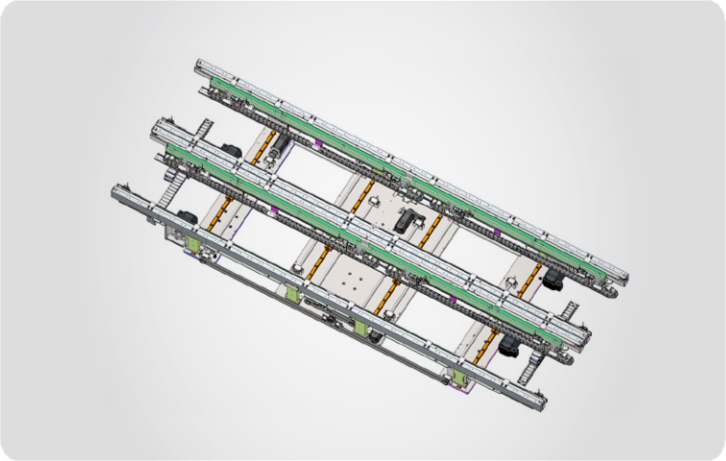

Double-Track Module

Optimization of carrier plate turnover time and improvement of UPH

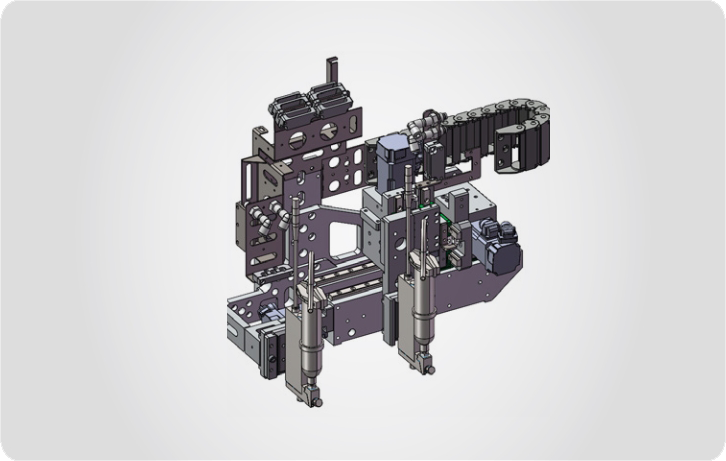

Double-Valve Asynchronization Module

Achievement of double-valve synchronization / asynchronization and double-valve switching for dispensing, and auxiliary valve with compensation function

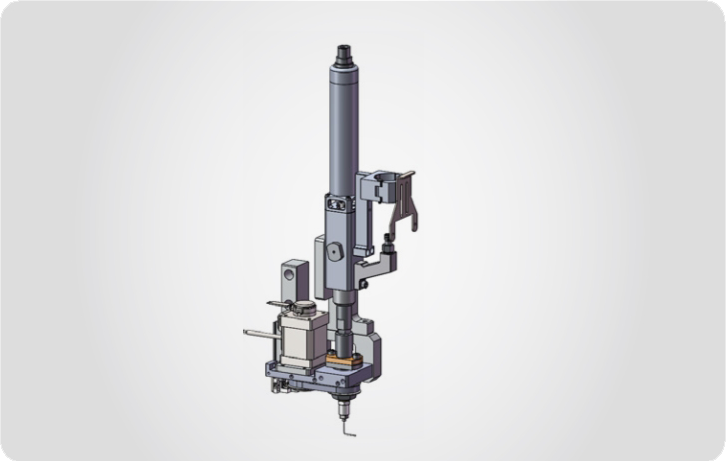

360º Rotation Module

Suitable for side dispensing process of connectors

Double-Execution Module

Four-valve synchronous dispensing can be configured, and is compatible with small-size product panelization operation

FS800 Series

FS800 Series

| Model | Single-Track Dispensing Range (W*D) | Double-Track Dispensing Range (W*D) |

| FS800F12 | 1200*800mm | 1200*400mm |

| FS800F15 | 1500*800mm | 1500*400mm |

| FS800F20 | 2100*800mm | 2100*400mm |

| FS800F25 | 2600*800mm | 2600*400mm |